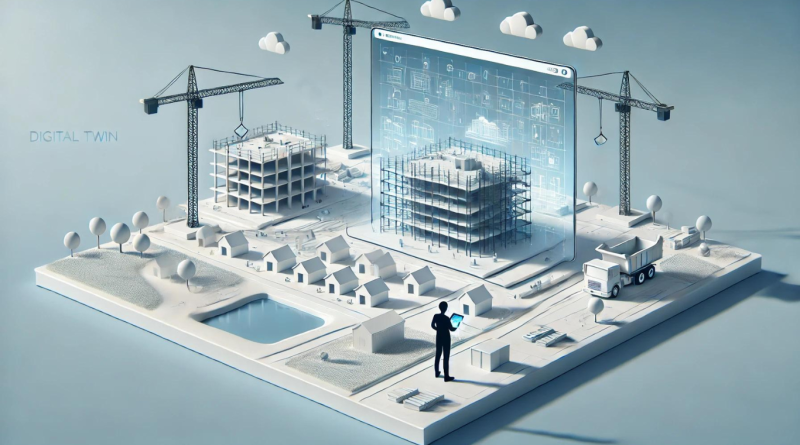

In construction technology, the term “digital twin” is gaining traction. Once the stuff of futuristic visions, digital twin technology is now being used in various industries to optimize performance, improve efficiency, and enhance decision-making. But what exactly is a digital twin, and will it ever become a practical tool in housing and small commercial construction?

This article aims to break down the concept of digital twin technology and explore whether it will become a major factor in constructing homes and small commercial buildings.

What Is a Digital Twin?

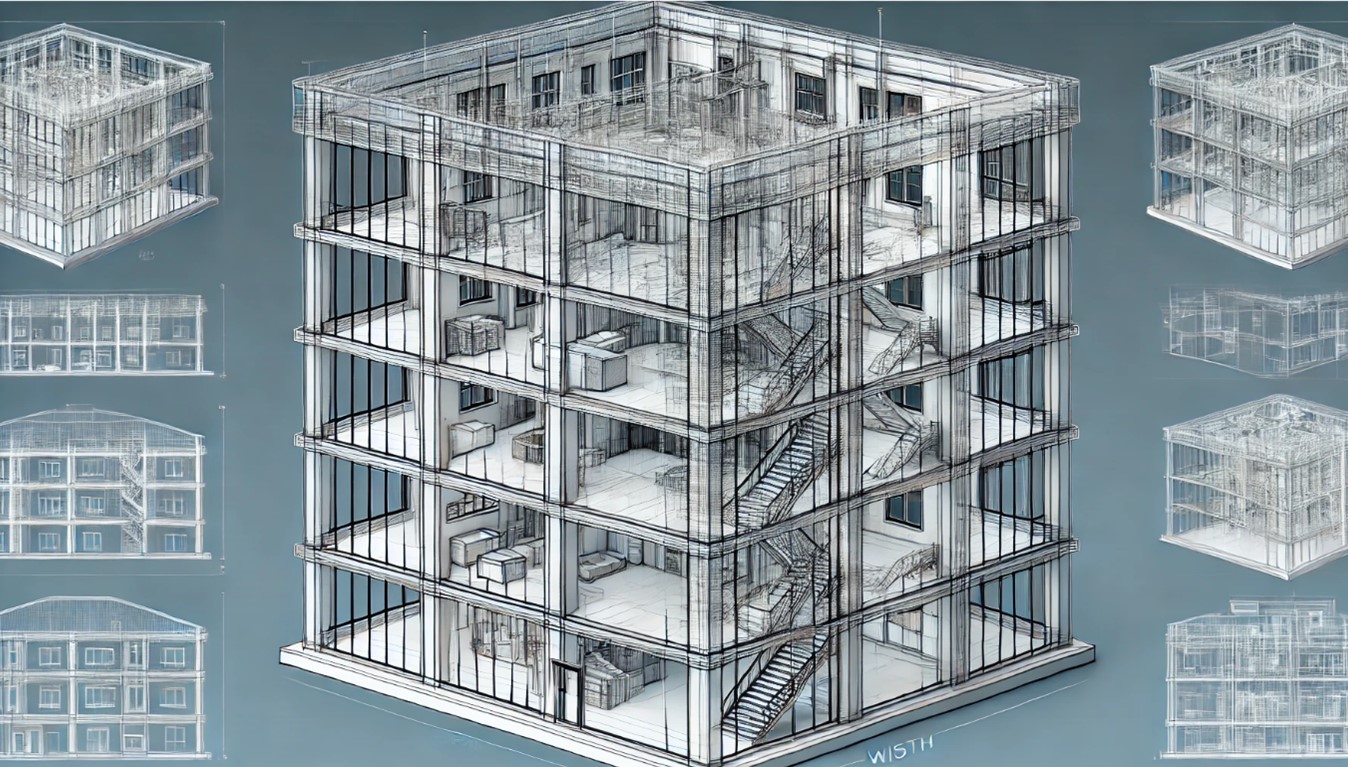

A digital twin is a virtual representation of a physical object or system. It’s more than just a 3D model; a digital twin includes detailed data about the real-world counterpart and can simulate how it will behave under various conditions. This digital replica continuously updates with real-time data collected from sensors or other monitoring tools embedded in the physical object or structure. The result is a highly accurate, dynamic digital copy that reflects the current state and performance of the physical asset.

In construction, a digital twin could be a replica of an entire building or its components, like a foundation or HVAC system. By integrating data from these elements, construction professionals can visualize, analyze, and predict how the building will perform throughout its lifecycle—from design and construction through operation and eventual demolition or repurposing.

The Origins and Evolution of Digital Twin Technology

Originally developed for use in industries like manufacturing, aerospace, and automotive design, digital twin technology was primarily employed to optimize the performance of high-cost assets. For example, NASA used digital twins to simulate and monitor space shuttle systems. The ability to monitor real-time performance remotely and predict outcomes based on simulation was essential for NASA’s missions.

In construction, the potential of digital twin technology is still in the early stages of adoption. According to a recent article on the future of construction published by Modular Home Source, digital twin technology is gradually being introduced in large-scale commercial and infrastructure projects but has yet to make significant inroads into housing or small commercial construction. While many recognize its potential benefits, there are several hurdles that need to be overcome before it becomes a standard tool in the building of homes and smaller structures.

Digital Twin Technology in Construction

In construction, a digital twin can be used at every stage of a building’s lifecycle—from planning and design through construction, operation, and maintenance. The construction process typically involves numerous stakeholders, including architects, engineers, contractors, and building owners. Each of these parties contributes to and depends on data throughout the project. Digital twins allow for better coordination between these groups, reducing errors, rework, and miscommunication.

Key uses of digital twin technology in construction include:

Planning and Design: Digital twins can create highly accurate models of a building’s structure and systems. By simulating various scenarios, architects and engineers can predict how the building will perform before construction even begins. This includes simulating structural integrity, energy consumption, and sustainability features.

Construction: During construction, digital twins can provide real-time updates on progress. Sensors embedded in construction equipment, materials, or even the site itself can monitor changes and provide data that is fed into the digital twin. This enables contractors to adjust schedules, resources, and plans based on real-time data.

Operation and Maintenance: After construction, the digital twin continues to serve as a living model of the building. Facility managers can use the twin to monitor building systems such as HVAC, lighting, and security, identifying potential issues before they become problems. By predicting maintenance needs and avoiding downtime, digital twins can extend the lifespan of a building and reduce operational costs.

Benefits of Digital Twin Technology

The potential benefits of digital twin technology are clear, especially for larger and more complex projects. According to Toobler, digital twin technology offers a range of advantages that can revolutionize construction practices:

Better Decision-Making: With real-time data and simulations, project managers can make more informed decisions, reducing costly mistakes.

Improved Collaboration: All stakeholders have access to the same data, making coordinating across teams easier and reducing misunderstandings.

Predictive Maintenance: Digital twins can forecast when maintenance is needed, reducing the risk of unexpected breakdowns and extending the life of building components.

Sustainability: Digital twins help designers and builders create more eco-friendly buildings by simulating various energy consumption and sustainability scenarios.

Cost and Time Efficiency: Real-time data and predictive insights can lead to faster construction timelines and reduced labor and material costs.

Will Digital Twin Technology Become a Factor in Housing and Small Commercial Construction?

While digital twin technology holds great promise, there are several challenges that make it difficult to implement in housing and small commercial construction at scale.

Cost

One of the primary barriers to adopting digital twin technology in housing is the cost. Implementing digital twins requires an investment in sensors, data integration systems, and specialized software. These costs can be justified in large commercial or infrastructure projects, where small gains in efficiency translate into significant financial benefits. However, for small residential projects, the return on investment (ROI) might not yet be compelling enough to justify the added expense.

Small construction firms may not have the budget to invest in the necessary technology or hire the specialized personnel needed to manage it. Without economies of scale, the costs of implementing digital twin technology may outweigh the potential benefits in the housing sector.

Complexity

The construction of a home or small commercial building involves fewer complex systems than a large commercial project or infrastructure development. This reduced complexity means that many of the predictive capabilities offered by digital twin technology may not be as critical. For example, while monitoring the real-time performance of a complex HVAC system in a high-rise might save significant operational costs, this may not be as important for a single-family home.

Additionally, the expertise required to fully implement and leverage digital twins is still concentrated in larger firms with specialized teams. Smaller construction companies might struggle to adopt the technology without significant investment in training or hiring.

Adoption Lag

Digital twin technology is still relatively new in the construction industry. While there’s no doubt that it has potential, the industry’s notoriously slow adoption of new technologies means that it could take years before digital twins become widespread in housing construction. According to Modular Home Source, digital twin technology could become a tool in offsite construction, especially as more factories and developers recognize its value in prefabrication and modular housing.

What the Future Holds for Digital Twin Technology in Housing

Despite these challenges, digital twin technology has the potential to play a role in housing and small commercial construction in the future. As the technology becomes more affordable and easier to use, it could be particularly useful in offsite construction, where buildings are prefabricated in factories before being assembled on-site. In this context, digital twins could streamline the entire process, improving coordination between factory production and on-site assembly.

Additionally, as smart home technology continues to advance, digital twins may play a role in integrating various systems within the home. For example, a digital twin could monitor a home’s energy usage, predict when maintenance is needed, or even suggest ways to optimize comfort and efficiency for homeowners.

Modcoach Note

Digital twin technology has the potential to transform the construction industry by providing real-time insights, predictive analytics, and better decision-making. While it has already found success in large commercial and infrastructure projects, its adoption in housing and small commercial construction is still limited by cost, complexity, and slow industry adoption. However, as technology advances and becomes more accessible, the benefits of digital twins may soon outweigh the challenges, making them a powerful tool in the future of construction.

For housing and small commercial construction, particularly in the offsite and modular sectors, the digital twin revolution could be just around the corner.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher