If you’ve ever worked in a factory, you know one thing for sure—rules are everywhere. It doesn’t matter if it’s a state-of-the-art offsite construction facility or a small mom-and-pop operation; every factory functions like a homeowners association (HOA). There are rule makers, rule enforcers, rule complainers, and, of course, rule breakers.

At their best, rules keep a factory running smoothly, ensuring efficiency, safety, and quality. At their worst, they create unnecessary bureaucracy, slow down production, and frustrate employees to the point of burnout. But not all rules are created equal, and not everyone follows them the same way. Let’s break it down.

The Four Levels of Rule Adherence

1. The Rule Maker

These are the higher-ups, the executives, the corporate policy creators. They draft factory-wide policies meant to standardize operations, ensure compliance, and, let’s be honest, cover their bases in case something goes wrong. Some of their rules are essential—like safety protocols—but others? Not so much.

2. The Rule Follower

These are the workers who take every rule seriously. They clock in on time, follow the handbook to the letter, and wouldn’t dream of taking an unauthorized shortcut. They keep things running, but they also might find themselves stuck in a system that isn’t always efficient.

3. The Karens of Rules

We all know this person. They don’t just follow the rules—they enforce them with the passion of a neighborhood HOA president who measures grass height with a ruler. They thrive on calling people out for minor infractions, even if those infractions have zero impact on productivity. They don’t bend, they don’t compromise, and they often make work more frustrating than it needs to be.

4. The Rule Breaker

These are the rebels of the factory floor. Some are reckless, ignoring safety procedures and cutting corners. Others are the creative problem-solvers who see inefficiencies and figure out better ways to do things—often bending or outright ignoring outdated rules in the process. Ironically, some of the best innovations come from rule breakers who challenge the system.

The Evolution of Rules in a Factory

Rules don’t just appear overnight. They build up over time, layer by layer, like sediment in a riverbed. Some are necessary, some are just for show, and some make no sense at all.

- The Inherent Rules – These are the unwritten rules. Don’t stand in someone’s way. Don’t touch another worker’s tools. Don’t eat your lunch on the production line.

- The Industry Rules – These are the big, unavoidable ones—safety codes, labor laws, OSHA regulations. Break these, and you’re looking at hefty fines.

- The Factory Rules – These come from corporate leadership and apply across the board, from dress codes to quality control measures.

- The Department Rules – What works for the framing department doesn’t necessarily work for the finishing crew, so different departments have their own sets of guidelines.

- The Manager Rules – Some managers add their own personal spin, whether it’s mandatory pre-shift meetings or limiting bathroom breaks.

- The Petty Rules – These are the rules that exist just because someone in charge got annoyed by something one time. No coffee mugs at your workstation? No talking during the first hour of a shift? These are the rules that drive workers crazy.

- The Common-Sense Rules – Show up on time. Do your job. Don’t break expensive equipment. These are the rules that everyone can agree on—yet somehow, they still need to be written down.

Who Actually Makes the Rules?

If you think rules are just handed down from the top, think again. Every level of management has its own say, which is why the rulebook keeps getting thicker every year.

- Upper Management Rules – Usually about cost-cutting, safety, and making investors happy.

- Investor Rules – Profitability comes first, so if a rule saves money, it sticks.

- Middle Management Rules – Designed to keep the factory running efficiently (or, at the very least, to make their lives easier).

- Department Rules – Tailored to specific job functions, which can either make sense or create unnecessary headaches.

- Individual Department Manager Rules – Sometimes helpful, sometimes personal pet peeves disguised as policies.

When Rules Go Too Far

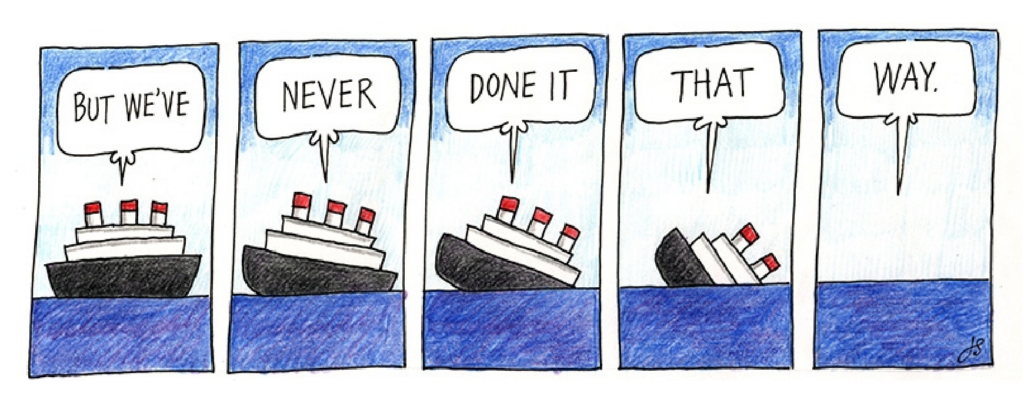

Here’s the problem: the longer a factory has been around, the more rules it accumulates. Over time, these rules become so deeply entrenched that no one even remembers why they exist. Workers start getting frustrated, productivity slows down, and the culture shifts from innovation to compliance.

Ever heard the phrase, “That’s just how we’ve always done it”? That’s a clear sign that the rules have taken over. When rules exist for the sake of existing—rather than to improve workflow or safety—workers start tuning them out. That’s when dissatisfaction grows, and good employees start heading for the exit.

The Balance Between Structure and Flexibility

Rules aren’t inherently bad. Without them, factories would be chaotic, unsafe, and impossible to manage. But when rules go unchecked, they stifle creativity, frustrate employees, and slow down progress.

The best-run factories are the ones that regularly evaluate their rulebooks, cutting out the nonsense and keeping only what truly matters. The worst-run factories? They’re the ones that operate like an HOA—where the rules just keep stacking up, and nobody’s happy.

So, if your factory feels like a rule-heavy HOA, maybe it’s time for a change. Because nobody wants to work in a place where the rulebook is thicker than the employee handbook.

.

Gary Fleisher, The Modcoach, writes about the modular and offsite construction industry at Modular Home Source.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher