Somewhere between a pile of sawdust and a field of corn lies the future of modular housing—and it’s being built one printed layer at a time.

At the University of Maine’s Advanced Structures and Composites Center, a quiet revolution is underway. Their project, BioHome3D, has captured the imagination of architects, offsite innovators, and environmentalists alike by demonstrating something once thought impossible: that a house can be grown and printed at the same time.

No steel. No concrete. No foam insulation. Just two humble ingredients—wood waste and corn-based resin—combined into a printable bio-composite that’s changing the way we think about construction materials, sustainability, and modular design.

A Printed Home That Grew From the Forest and the Farm

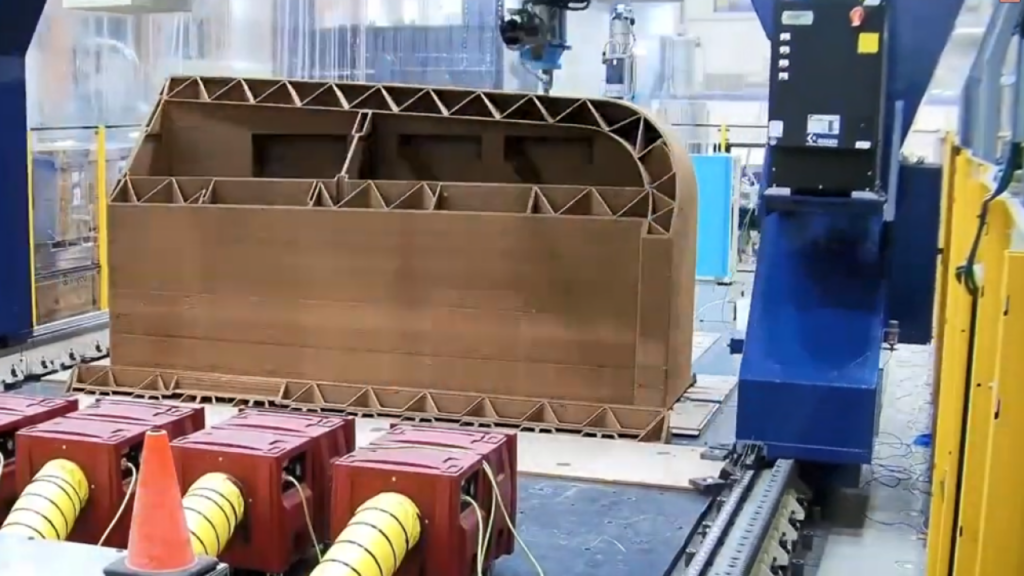

The idea sounds like science fiction. A 3D printer—bigger than a school bus—whirs to life and begins extruding a warm, fibrous paste onto a large flatbed. Hours later, a complete structure rises from the platform: walls, roof, floor, and insulation all printed from the same renewable material.

The secret is in the bio-composite mix. The wood waste comes from Maine’s plentiful timber industry—essentially the leftovers from sawmills and forest management. Mixed with a corn-based resin, it creates a renewable, lightweight, and surprisingly strong material that can be molded into virtually any shape.

According to Dr. Habib Dagher, Executive Director of the Composites Center, the material isn’t just green—it’s smart. “It insulates better than traditional materials, it resists mold and pests, and most importantly, it can be recycled or composted at the end of its life,” Dagher says. “This is truly cradle-to-cradle design.”

A Modular Dream: Factory-Built, Locally Sourced

BioHome3D isn’t just a clever materials story. It’s also a modular construction success. The entire home—about 600 square feet in its current version—was printed in four major components: roof, floor, and two walls. These were printed offsite, trucked to the installation location, and assembled in under a day. Electrical wiring and mechanical systems were pre-integrated during printing, cutting down build time and reducing labor needs dramatically.

Imagine the implications for disaster relief housing, affordable rural developments, or infill lots in high-demand urban cores. No nails, no framing crews, no drywall finishing teams. Just print, ship, set, and go.

In a state like Maine, which struggles with both affordable housing shortages and declining rural economies, this local-loop approach could be a lifeline. “We’re using Maine-grown materials, Maine-grown talent, and solving Maine’s housing problems,” says Dagher. “But the impact could go far beyond our borders.”

Rewriting the Codebook—Literally

Of course, innovation always meets friction when it comes to building codes. One of the hurdles facing BioHome3D is regulatory acceptance. No one’s quite sure what chapter of the codebook to put a 3D-printed, biodegradable, corn-and-wood house into. But the team at the Composites Center is working with state and federal officials to create a path forward.

They’re also collecting detailed data on insulation performance, fire resistance, wind uplift, and structural integrity. Preliminary tests have shown the walls outperform traditional stick-frame structures in thermal resistance and moisture management—two critical issues in both cold climates and storm-prone regions.

The Future Is (Biodegradable) Modular

The big question now is scalability. Can BioHome3D be mass-produced? Can printing times be shortened? Can we source enough biocomposite material for thousands—or millions—of homes?

Dagher is confident. The next step is building a dedicated BioHome3D factory, capable of printing homes at scale for municipalities, developers, and even private buyers. With interest growing across the U.S.—particularly in states facing housing crises—this isn’t a niche experiment anymore. It’s a model.

For the modular home industry, BioHome3D offers both inspiration and a challenge. It’s a vivid reminder that sustainable, beautiful, and functional housing doesn’t have to come from concrete panels or steel frames. It can come from the forest floor and the cornfield—and be built layer by layer with zero waste.

What’s the Future Hold?

For decades, offsite housing has promised speed, efficiency, and affordability. BioHome3D adds something rare to that mix: hope. Hope that we can build smarter. Hope that homes can heal the planet rather than harm it. And hope that the future of housing might just smell faintly of pine and popcorn.

CLICK HERE to read more about this home

.

Gary Fleisher, The Modcoach, writes about the modular and offsite construction industry at Modular Home Source.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher