Let’s be honest: most of us entered this field thinking modular construction would be faster, cheaper, better. We pictured a smooth-running factory, a well-oiled logistics system, and happy clients thrilled to see their dream home arrive in two halves on the back of a truck. Instead, we got value engineering meetings, misaligned modules, and developers who think “modular” means “magic.”

But it’s not all chaos and craned-in heartbreaks. Every modular project—especially the messy ones—teaches us something. Sometimes it’s a technical insight. Sometimes it’s a life lesson like “always confirm the set date after the foundation is actually poured.” These nuggets of wisdom are earned, not handed out with your hard hat.

So, whether you’re building your first box or your five hundredth, consider this your unofficial survival guide—25 nuggets of hard-earned modular truth that might just save your schedule, your sanity, or your last remaining margin.

Read them, share them, live them…

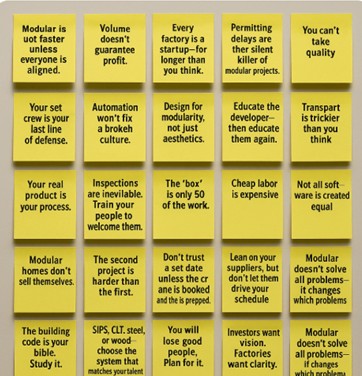

Here are my 25 nuggets of wisdom that everyone in the modular construction industry—whether factory owner, developer, GC, architect, supplier, or consultant—should keep top of mind:

1. Modular is not faster unless everyone is aligned.

If the land isn’t ready, the factory’s speed becomes irrelevant. Coordination is everything.

2. Volume doesn’t guarantee profit.

A full production schedule can still lose money if pricing, labor, and waste aren’t under control.

3. Every factory is a startup—for longer than you think.

Even experienced builders underestimate how long it takes to stabilize operations.

4. Permitting delays are the silent killer of modular projects.

No module moves until every stamp is in place. Get your AHJs on board early.

5. You can’t fake quality.

One bad module on-site can destroy a reputation built over years.

6. Your set crew is your last line of defense.

They can make a mediocre module look perfect—or a perfect one look like junk.

7. Automation won’t fix a broken culture.

Robots can’t solve communication breakdowns, poor leadership, or unclear goals.

8. Design for modularity, not just aesthetics.

Many architects still design “modular projects” like site-built homes—then wonder why costs balloon.

9. Educate the developer—then educate them again.

Most developers don’t understand modular. If you don’t set expectations, you’ll eat the change orders.

10. Transport is trickier than you think.

Permits, escorts, routes, weather—hauling boxes is an art, not a given.

11. Your real product is your process.

Repeatable quality comes from processes, not from heroic efforts by individuals.

12. Inspections are inevitable. Train your people to welcome them.

A well-managed inspection is an opportunity to build trust with regulators.

13. The ‘box’ is only 60% of the work.

Finish crews, site prep, hookups, stairs, and punch lists are where time and budgets vanish.

14. Cheap labor is expensive.

Underpaying today creates callbacks, warranty costs, and high turnover tomorrow.

15. Not all software is created equal.

ERP and scheduling tools must work in your workflow, not just look good in a demo.

16. Modular homes don’t sell themselves.

You still need great marketing, smart salespeople, and trust from your buyers.

17. The second project is harder than the first.

Everyone brings energy to project #1. The real test is building sustainable systems after the hype.

18. Don’t trust a set date unless the crane is booked and the site is prepped.

Hope is not a schedule.

19. Lean on your suppliers, but don’t let them drive your schedule.

Vendor delays ripple through your factory fast.

20. Every module is a prototype unless you lock your SKUs.

Changing specs on the fly guarantees chaos.

21. The building code is your bible. Study it.

Modular construction is highly regulated. Shortcut it and you’ll pay later.

22. SIPs, CLT, steel, or wood—choose the system that matches your talent.

Material choices should follow skill availability, not trends.

23. You will lose good people. Plan for it.

Cross-train, document, and create a bench. No one stays forever.

24. Investors want vision. Factories want clarity.

Speak differently to each. Vision raises capital. Clarity builds houses.

25. Modular doesn’t solve all problems—it changes which problems you face.

It’s not easier. It’s different. And different requires a new mindset.

.

With over 9,000 published articles on modular and offsite construction, Gary Fleisher remains one of the most trusted voices in the industry.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher