In Japan, Sekisui House quietly builds over 50,000 precision homes a year, evolves its floorplans annually like a new car model, and somehow manages to do all this without collapsing under the weight of over-promising and under-planning.

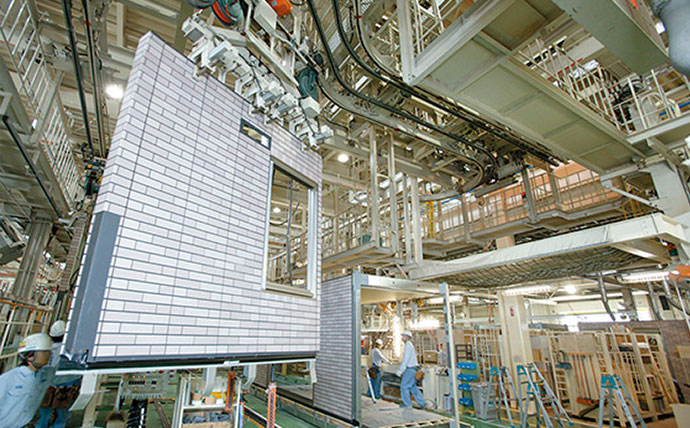

photos – Sekisui House

Meanwhile, in the U.S., we’ve watched some modular startups go up in flames like fireworks on the Fourth of July.

Why is that?

Why can one country treat modular housing like a refined, scalable product—and another treat it like a Silicon Valley moonshot that explodes on the launch pad?

Sekisui House: The Toyota of Homes

Let’s start with Sekisui. This is a company that’s been around for over 60 years, has R&D departments the size of a college campus, and treats innovation as a quiet discipline—not a PR stunt. Their business model may seem simple at first glance, but the execution is what makes it extraordinary. Sekisui designs homes that can be mass-produced with factory efficiency while still feeling personal and customizable to the buyer. That’s not an easy balance to strike.

What makes their approach unique is how deeply they’ve embedded vertical integration. Sekisui doesn’t outsource the critical pieces of the process. Instead, they design and manufacture their own framing systems, finishes, and building components. They maintain complete control from blueprint to jobsite. And unlike many U.S. builders, they treat each new home model like a product line—something to be refined and improved with each passing year, much like the auto industry does with vehicle models. If something can be made more sustainable, more efficient, or more attractive, they implement it and roll it out in the next version. And when a Sekisui home reaches the end of its lifecycle—whether it’s 30 or 40 years later—it’s not torn down in frustration. It’s often taken apart strategically, with materials repurposed or recycled, as part of a well-planned evolution of the built environment.

The American Startup Playbook: Hype Now, Headaches Later

Now let’s shift the lens to our own backyard. In the U.S., the typical modular startup story is one we’ve seen many times. A new factory bursts onto the scene with a bold mission to reinvent housing. They bring in tech investors, boast about a revolutionary software stack or robotic assembly line, and deliver a series of press releases that sound more like science fiction than construction.

But after the fanfare, reality sets in. Timelines slip. Material shortages get blamed. Factories are forced to pause production to troubleshoot bugs in the system. The leadership team quietly reshuffles. More rounds of capital are burned through with little to show for it. What was once a media darling becomes a ghost town of missed opportunity.

The problem isn’t just execution—it’s mindset. Too many of these startups believe housing is a software problem or a branding problem, when really it’s a supply chain and coordination problem. Construction isn’t like launching a new app. It’s messy, it’s physical, it’s slow to change, and it depends on dozens of moving parts working together in real time. Many U.S. startups fail not because they lack innovation, but because they ignore the boring, hard parts of building repeatable systems and scalable processes. They forget that the foundation of every great modular factory isn’t technology—it’s discipline.

What Japan Does That We Don’t

Here’s the blunt truth: Sekisui House isn’t trying to be cool. They’re trying to be consistent. That’s a big difference—and it makes all the difference. From the moment a customer orders a home to the final quality inspection on site, every step of their process is connected. The design team doesn’t work in isolation. The production team doesn’t guess. The installation crews are trained in the system, not just the product. The systems in place ensure that communication gaps, human error, and guesswork are minimized.

One of the keys to Sekisui’s success is that they treat innovation as an ongoing process, not a one-time disruption. They update their product lines every year—not because the market demands it, but because they’ve trained themselves to expect improvement. Their customers benefit from homes that quietly get better with each model year, even if they don’t realize it.

Contrast that with the U.S., where many modular factories still use outdated software, rely on disjointed crews, and approach every project as if it’s the first time it’s ever been done. The result is a chaotic patchwork of semi-custom workarounds that kill profit margins and timelines. We tend to romanticize disruption and innovation in America—but in modular construction, it’s boring reliability that wins.

The Real Innovation: Stability

There’s something quietly radical about not chasing headlines. In an industry that loves to hype, Sekisui and its peers in Japan have made an art form out of staying out of the spotlight. They don’t need flashy renders or splashy media tours to prove their worth. They simply keep delivering homes that meet performance expectations, serve real market needs, and age gracefully.

While U.S. factories often bite off more than they can chew—chasing one-off luxury homes, overpromising on delivery schedules, or jumping into massive affordable housing contracts without the infrastructure—Sekisui focuses on doing a few things incredibly well. Their homes are reliable, precise, and easy to maintain. They aren’t built to be talked about. They’re built to be lived in.

And that may be the most disruptive thing of all: showing the world that true innovation is not a sudden spark—it’s a steady flame that keeps burning.

What We Can Steal (Politely)

We’ll never be Japan. Our market dynamics, land use regulations, labor challenges, and zoning complexities are different. But that doesn’t mean we can’t borrow a few important pages from their playbook. For starters, American modular factories should start thinking of themselves less like general contractors and more like product manufacturers. The factory itself should operate more like an assembly line, not a workshop.

Instead of trying to serve every market segment or chase every new niche, focus on getting one thing right. Build a small number of models, refine them constantly, and let the product mature. Once that foundation is strong, iterate every year with improvements in energy efficiency, ease of installation, or cost savings. Think in terms of 5-year and 10-year product roadmaps, not just next quarter’s cash flow.

And here’s a big one: treat your customer like a long-term user, not a one-time buyer. Just like automakers offer warranties, service plans, and upgrade paths, modular builders can start thinking about how to keep homeowners engaged for decades—offering refresh kits, component upgrades, and even resale support.

And finally, stop outsourcing the core of your value. Whether it’s design, production, or final site work, the more pieces you control, the more consistent your product will be. Consistency builds reputation. And reputation, unlike a VC check, doesn’t run out.

The next great American modular success story probably won’t come from another headline-chasing startup. It might come from a quietly competent factory in a Midwest town, run by people who understand that building a great product isn’t about raising the most money—it’s about raising the bar, one home at a time.

And if they happen to learn a thing or two from Japan along the way? Even better.

.

With over 9,000 published articles on modular and offsite construction, Gary Fleisher remains one of the most trusted voices in the industry.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher