“The offsite industry’s real challenge isn’t artificial intelligence—it’s artificial impatience.”

AI isn’t new—but its current speed of learning, acquisition, and integration is something we’ve never encountered before. The offsite, modular, and component construction industry, long criticized for being slow to adopt innovation, may now be facing a moment where the very tools we’ve finally embraced are evolving beyond our ability to strategically use them.

AI’s Expanding Role

AI is no longer confined to design optimization or scheduling software. It’s infiltrating every layer of offsite production. In factories, AI-driven vision systems are now monitoring assembly accuracy in real time, while predictive analytics determine when equipment will fail before it happens. Generative design tools can produce hundreds of modular layout options within minutes, optimizing for cost, code, and aesthetics. Even supply chain algorithms are forecasting material delays and pricing fluctuations weeks in advance, allowing better planning—if we know how to use the data.

In short, AI is doing more than we ever asked it to—it’s learning from us faster than we can train ourselves to manage it.

The Human Lag

The problem isn’t that AI is moving too fast—it’s that we aren’t. Most factory executives and managers are still measuring productivity in terms of shifts, output, and labor cost per square foot. AI, on the other hand, measures opportunity in terabytes, probabilities, and predictive insights. That creates a widening gap between what AI can do and what humans allow it to do.

Strategic planning, once the cornerstone of experienced leadership, is now being replaced by AI-driven decision systems that often feel detached from the lived experience of those running factories. Many managers have access to these tools but lack the training, time, or trust to use them effectively. The cultural shift from human instinct to machine intelligence is proving far more difficult than installing the software itself.

Consequences Ahead

If this pace continues, several consequences are almost inevitable.

Decision-making will increasingly rely on AI interpretations. The risk isn’t that AI will make mistakes—humans have done that for centuries—but that humans will stop questioning its conclusions. When judgment is replaced by blind acceptance, innovation becomes imitation.

There’s also the looming risk of skill erosion. As AI handles more design, scheduling, and quality control, we may lose the very professionals who built the foundation of our industry through hard-earned intuition and craft. Their ability to “read” a project, sense issues before they surface, or adapt in the field can’t easily be replicated by algorithms.

Then there are ethical and liability challenges. When an AI program designs a wall system that fails or allocates materials inefficiently, who’s responsible—the software provider, the factory, or the operator who clicked “approve”? The law is still catching up to technology, and that gray area could become costly for early adopters.

Lastly, innovation overload may become a silent productivity killer. Factories that rush to implement too many disconnected tools too quickly could find themselves drowning in digital clutter. AI may end up creating more confusion than clarity, leaving teams overwhelmed rather than empowered.

The Path Forward

The winners won’t be those who adopt the most AI—but those who adopt it wisely. The real power of artificial intelligence lies in its partnership with human intelligence. The factories and firms that thrive will be the ones that use AI not to replace human insight but to expand it. They’ll build cultures where managers challenge what the data suggests, not just follow it, and where younger professionals are trained to think critically about automation rather than depend on it blindly.

We don’t need to “keep up” with AI; we need to guide it. The offsite industry’s real challenge isn’t artificial intelligence—it’s artificial impatience. Our success won’t depend on how fast we install AI, but on how thoughtfully we align it with the experience, creativity, and judgment that no machine can yet replace.

.

With over 9,000 published articles on modular and offsite construction, Gary Fleisher remains one of the most trusted voices in the industry.

.

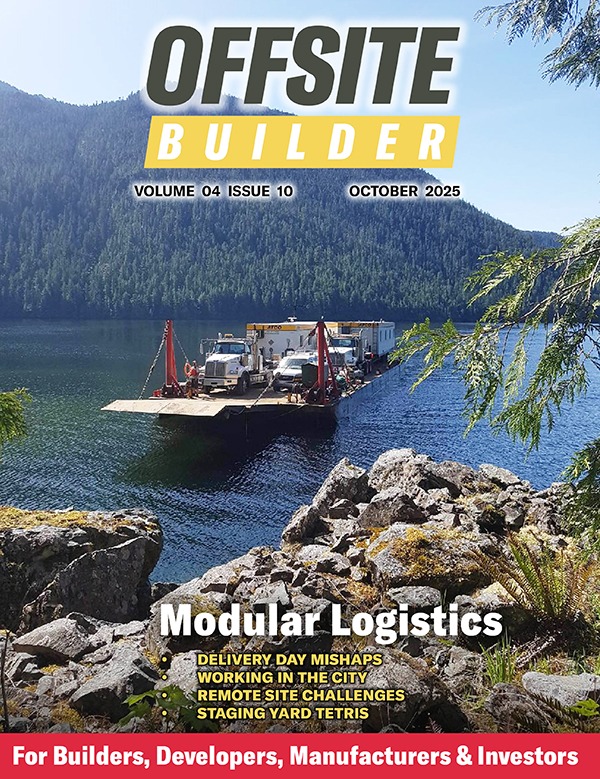

CLICK HERE to read the latest edition

Contact Gary Fleisher