Australia’s building sector is under pressure — housing demand is urgent, costs are rising, and labour is stretched. Enter modular construction: prefab modules, volumetric units, engineered offsite — promising faster delivery, consistent quality and lower waste.

But here’s the rub: modular still makes up less than 5 % of Australia’s building output. The transition from niche curiosity to mainstream choice is being held back by a handful of persistent challenges.

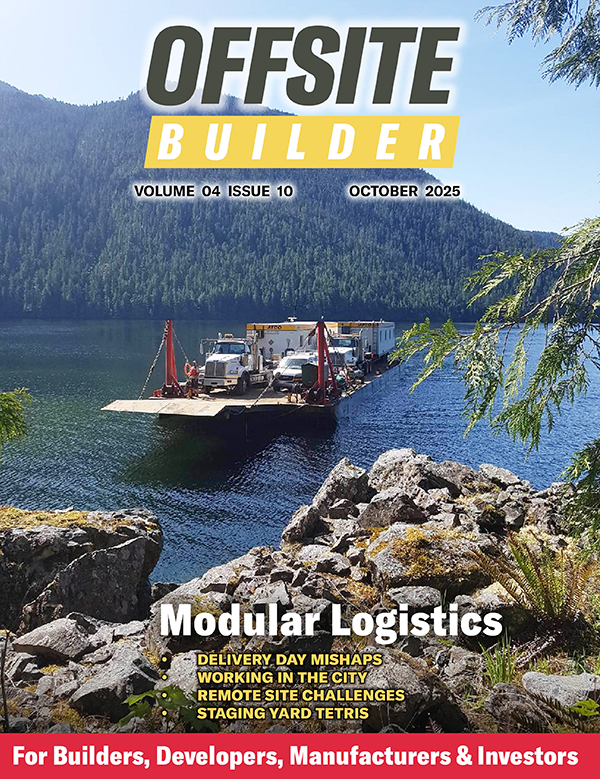

1. Logistics & integration

You can manufacture modules with near-perfect precision, but if transport, crane access, site sequencing and interface with civil/utility works aren’t nailed down, the gains vanish. Modular’s promise hinges on seamless linking of off-site and on-site.

2. Risk, contracts & capital

Modular demands decisions be locked in early. Traditional linear procurement models don’t always suit this shift. Designers, builders, manufacturers and developers must align from the get-go. Meanwhile, financiers and insurers want evidence — predictable outcomes, clear standards, risk transparency.

3. Codes, compliance & global supply chains

Australia’s building codes were largely written for in-situ construction. When modules get fabricated overseas, mismatches in standards, tolerances or materials create headaches for certifiers and owners. Bridging that gap — via tighter integration of local design, robust QA, and close alignment with Australian regulators — is essential.

4. Digital backbone

Modular tolerances demand precision. Tools like BIM, digital twins and robotics are no longer optional extras — they are core to ensuring that prefabs slot together accurately and predictably.

5. Scale, pipeline & culture shift

Without a reliable pipeline of repeat work, modular manufacturers struggle to justify investment. Governments can kickstart the shift by committing to multi-year procurement contracts for housing, health, education and social infrastructure. Over time, modular must be viewed not as a niche experiment, but as a central delivery pathway.

Plus, factory-based construction requires different skills — fewer tradies on site, more digital and manufacturing expertise.

Modular construction isn’t a silver bullet. But for scalable, repeatable building types—from multi-unit housing to student accommodation—it may well be Australia’s strongest lever for faster delivery, consistent quality and lower carbon footprints. The real test now lies in how smart projects at the fringes show the way forward.

Based on “Moving modular construction from niche to mainstream,” BTR News Australia

.

With over 9,000 published articles on modular and offsite construction, Gary Fleisher remains one of the most trusted voices in the industry.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher