Modular construction factories are built on consistency. That’s the promise: repeatable results, tightly managed workflows, and predictable quality. But that promise hinges on something else—layers of inspection, quality control, and compliance that ensure each module is up to code and client expectations.

For decades, these layers have relied on human judgment: quality assurance managers with clipboards, third-party inspectors walking the line, factory workers doing double checks before the module gets wrapped and shipped. But as AI and machine vision evolve at an astonishing pace, a new question is emerging—one that would’ve sounded like science fiction ten years ago:

Could modular construction’s QA and third-party inspections eventually be replaced—or at least enhanced—by remote AI inspections?

It’s not just a hypothetical. It’s a real conversation now happening in boardrooms, R&D departments, and on the factory floor.

The Inspection Status Quo: Manual, Repetitive, and Slowed by Schedules

Let’s be honest: traditional factory QA and inspection protocols are time-consuming. They require coordination between production, management, and outside inspectors who are sometimes scheduled days—or weeks—in advance. And if the module isn’t ready when the inspector arrives? Everyone waits.

Third-party inspectors, often representing state code compliance or HUD, still carry a lot of weight. But their tools haven’t changed much in decades. They’re walking with tablets instead of paper now, but the process is essentially the same: Look. Measure. Check a box.

In an industry that prides itself on innovation, this part of the modular process still runs on 20th-century workflows.

Enter AI: Watching Every Step in Real Time

Now imagine this:

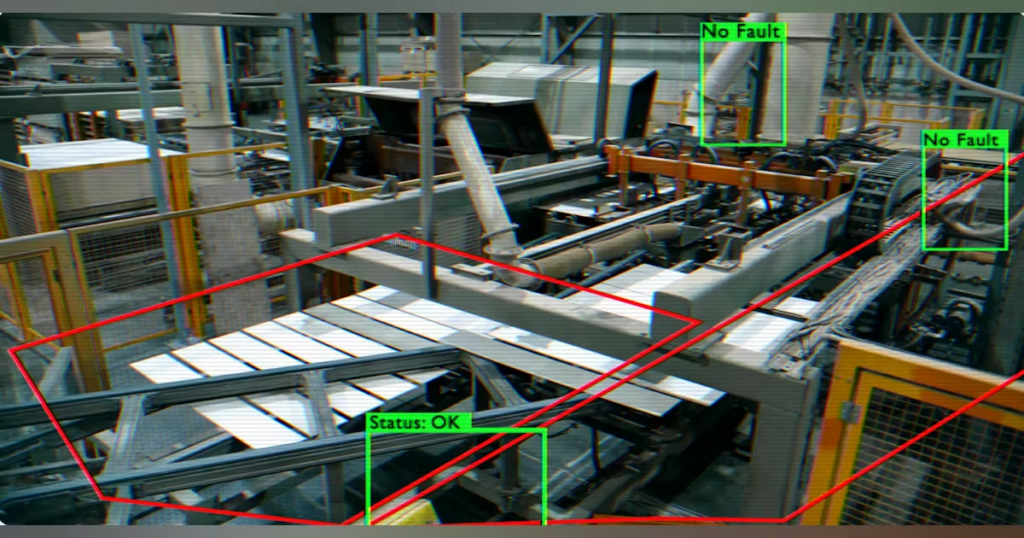

Dozens of cameras mounted at key checkpoints throughout the factory. AI-powered vision systems scanning every wire, joint, fastener, and cut. Software that knows the plan, the codebook, and the expected tolerances—and flags anything that deviates from the standard.

Not someday. This is already being tested in industries far more complex than housing—like aerospace, auto manufacturing, and semiconductor cleanrooms.

In those industries, AI doesn’t just catch flaws. It predicts them based on patterns. It learns from past mistakes. It doesn’t take coffee breaks or get distracted. It doesn’t miss the loose wire because it’s worried about its 2 p.m. dentist appointment.

And here’s the real kicker: these systems can be accessed remotely, meaning third-party inspectors could log in from anywhere in the world and see what’s happening in real-time or through a recorded digital twin of the process. Every weld, every plumbing run, every nail.

What Would This Change?

A fully digitized AI-driven inspection process could:

- Eliminate scheduling delays for inspections

- Provide 24/7 quality control oversight

- Create a permanent visual record of every step of the build

- Reduce subjectivity in QA calls

- Enable instant reporting and red-flag alerts

- Allow third-party verification without stepping foot in the factory

For large-scale modular factories working across multiple states or projects, this could be game-changing. It could also enable scaling—fast.

But What’s the Catch?

This is where the conversation turns from possibility to reality check.

- Regulations don’t allow it—yet. Most state housing authorities and HUD programs still require physical inspection from approved inspectors. Changing this would require a major shift in regulatory policy and trust in technology.

- AI still makes mistakes. While great at catching deviations, current AI systems don’t fully understand context. A wire slightly out of place might not be a code violation, but the AI might red-flag it anyway. Human judgment still matters—especially in edge cases.

- Cost and integration. Setting up AI inspection systems isn’t cheap or simple. It requires investment, training, and reworking the production flow.

And perhaps the biggest barrier: cultural trust. Many factory managers, inspectors, and even customers aren’t ready to hand over QA to an algorithm. They want a person walking the line, pointing, asking, verifying.

We trust people—flawed as we may be—more than we trust lines of code. At least, for now.

Where Are We Headed?

In the short term, expect a hybrid approach. Forward-thinking factories will begin adding AI and computer vision systems to assist human inspectors, not replace them. Think of it like a co-pilot, not an autopilot.

But down the road? As AI gets better, regulations evolve, and pressure to build faster increases, we may start to see fully remote inspections backed by AI become the norm. It will start with the low-hanging fruit—visual inspections, dimensional tolerances, image-based error tracking—and slowly move into more complex decision-making.

One day, a factory QA manager may walk the floor with an augmented reality headset, receiving real-time AI feedback as she moves. A third-party inspector may no longer need to visit the factory at all, instead auditing the build in real time via secure video, flagging corrections without ever booking a flight.

The Future is Watching

It’s worth noting that AI and robotics are advancing faster than most industries can adapt. While offsite construction is still catching up in some areas, the leap toward digitized quality assurance is coming—quietly, steadily, and with relentless precision.

Will robots replace inspectors entirely? Probably not in the next five years.

But will modular factories learn to embrace AI as a tool to improve consistency, speed up certification, and reduce liability?

Absolutely.

And the factories that adopt it early won’t just be ahead of the curve. They’ll be setting the new standard.

Are you seeing AI being tested in your QA process? Would your third-party inspectors trust it? Let’s talk.

.

Gary Fleisher, The Modcoach, writes about the modular and offsite construction industry at Modular Home Source.

.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher