Every once in a while, a company comes along that rewrites the rules for an entire industry. In the UK, that company might just be Tide Construction and its manufacturing arm, Vision Modular Systems. Together they’ve quietly achieved something most offsite firms only talk about — true vertical integration.

While many modular manufacturers struggle to align developers, contractors, financiers, and local inspectors, Tide and Vision simply are all of them. The group designs, develops, manufactures, transports, and assembles its own buildings — controlling the process from the first sketch to the final inspection. The results have been staggering: seven of Europe’s ten tallest modular residential buildings, more than 2,500 homes currently underway, and combined revenues approaching £255 million last year.

For an industry that often suffers from fractured supply chains and mismatched expectations, their success story may represent the next logical step for offsite construction worldwide.

Integration: The Missing Link

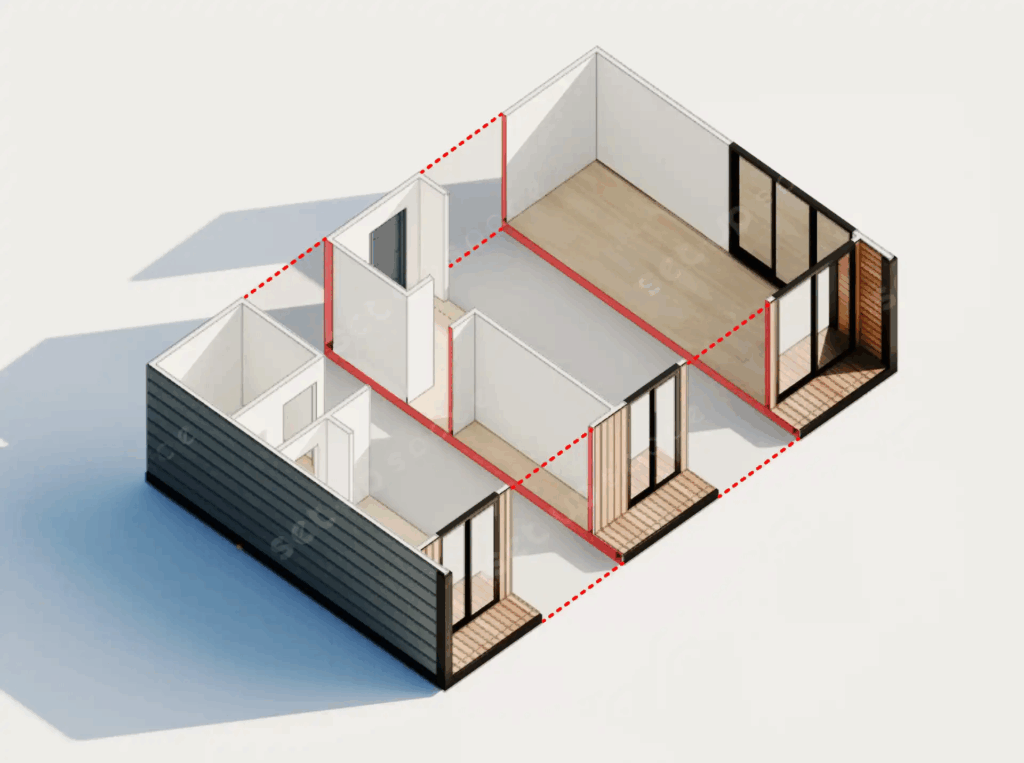

One of modular construction’s biggest challenges has always been coordination. Developers have their own goals, contractors have theirs, and manufacturers are left to interpret everyone’s vision while staying within design and schedule limits. Every handoff introduces risk — in design intent, logistics, financing, and accountability.

By merging these roles into a single ecosystem, Tide and Vision have removed the friction. Their design team isn’t hoping a factory can build what they draw; they’re designing for that factory. Their factory managers aren’t waiting for vague development schedules; they’re setting the schedules themselves. It’s a rare alignment where every department’s success depends on the same outcome.

Speed, Scale, and Simplicity

Fully integrated companies enjoy something the rest of the industry craves: predictability. With design, manufacturing, and assembly under one roof, Tide can deliver high-rise modular projects at a speed that traditional developers struggle to comprehend.

Every module fits into a precise production sequence. Supply chains are secured months ahead. On-site assembly runs like clockwork. There’s no need to juggle external bids, no finger-pointing between the developer and the contractor, and no long pauses waiting for permits or design clarifications.

That efficiency translates into lower costs, fewer delays, and more consistent quality — a trifecta that’s hard to achieve in the fragmented U.S. offsite market.

The Financial Edge

Integration isn’t just operational; it’s financial. By being both the developer and the builder, Tide and Vision capture value across the entire life cycle of a project. Profits aren’t diluted among five different entities. This makes it easier to finance new projects, invest in factory automation, and weather the inevitable market slowdowns.

It’s a business model that could protect modular companies from the cash-flow rollercoaster that has toppled so many promising startups. Instead of relying on outside developers to bring them work, integrated firms create their own pipelines.

Why It Makes Sense Now

The timing couldn’t be better. Global demand for housing is at an all-time high, and governments everywhere are pushing for faster, greener, and more affordable construction. Yet, as anyone in the industry knows, modular’s biggest barrier has never been technology — it’s coordination.

The integrated model solves that. It builds efficiency into the DNA of every project. And as supply-chain disruptions, financing risks, and code variations continue to frustrate standalone factories, integration offers something modular has always promised but rarely delivered: control.

Can It Work in the U.S.?

That’s the million-dollar question. The American modular industry has long been divided into specialists — developers, builders, manufacturers, and logistics providers all working independently. But as more companies struggle to scale, we may start to see the same logic that drove Tide and Vision’s rise cross the Atlantic.

Some early adopters are already experimenting with hybrid models — developers owning part of factories, manufacturers creating in-house design divisions, or contractors partnering permanently with specific plants. Each is a step toward a tighter, more resilient ecosystem.

If the industry’s goal is to grow beyond its current market share, the lesson is clear: stop handing off responsibility and start integrating it.

The Big Picture

When I built homes in the 1980s and 90s, I was thrilled just to see wall panels and roof trusses replace piles of raw lumber on a muddy job site. Today, seeing an entire development — hundreds of apartments or co-living units — roll out of a single coordinated operation still amazes me.

Tide Construction and Vision Modular Systems have shown what happens when an offsite company takes control of every piece of the puzzle. They’re not just building homes; they’re building the future business model for the entire industry.

.

With over 9,000 published articles on modular and offsite construction, Gary Fleisher remains one of the most trusted voices in the industry.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher