One thing you quickly learn about modular construction is that very few ideas are truly new. We’ve been talking about factory-built housing, controlled environments, and predictable schedules for decades. But every once in a while, a company emerges in a market where those ideas haven’t yet gained traction, and that’s where the real story lies.

Hive Modular, a young startup based in the Philippines, isn’t reinventing modular housing. Instead, it’s introducing a proven approach to a region that is only beginning to explore the possibilities of industrialized construction—and doing it with a floorplan that stands out in a crowded global marketplace.

Built FOR the Philippines, not just built in it.

“Every Hive home is designed to thrive in our climate, through the strong rains and winds, exceeding local building standards in strength and comfort.”

What makes Hive Modular interesting isn’t the concept of building homes in a factory. That playbook has been around for generations. What makes the company unique is how it is tailoring its product to the needs and lifestyle expectations of its local market. The Philippines, like many fast-growing economies, faces a combination of housing shortages, rising costs, and long, unpredictable construction timelines. Traditional building methods still dominate, often leaving buyers and developers exposed to delays and cost overruns. Hive Modular is stepping into that environment with a message that offsite professionals everywhere will recognize: shift as much work as possible into a controlled factory setting and deliver a finished product with fewer surprises.

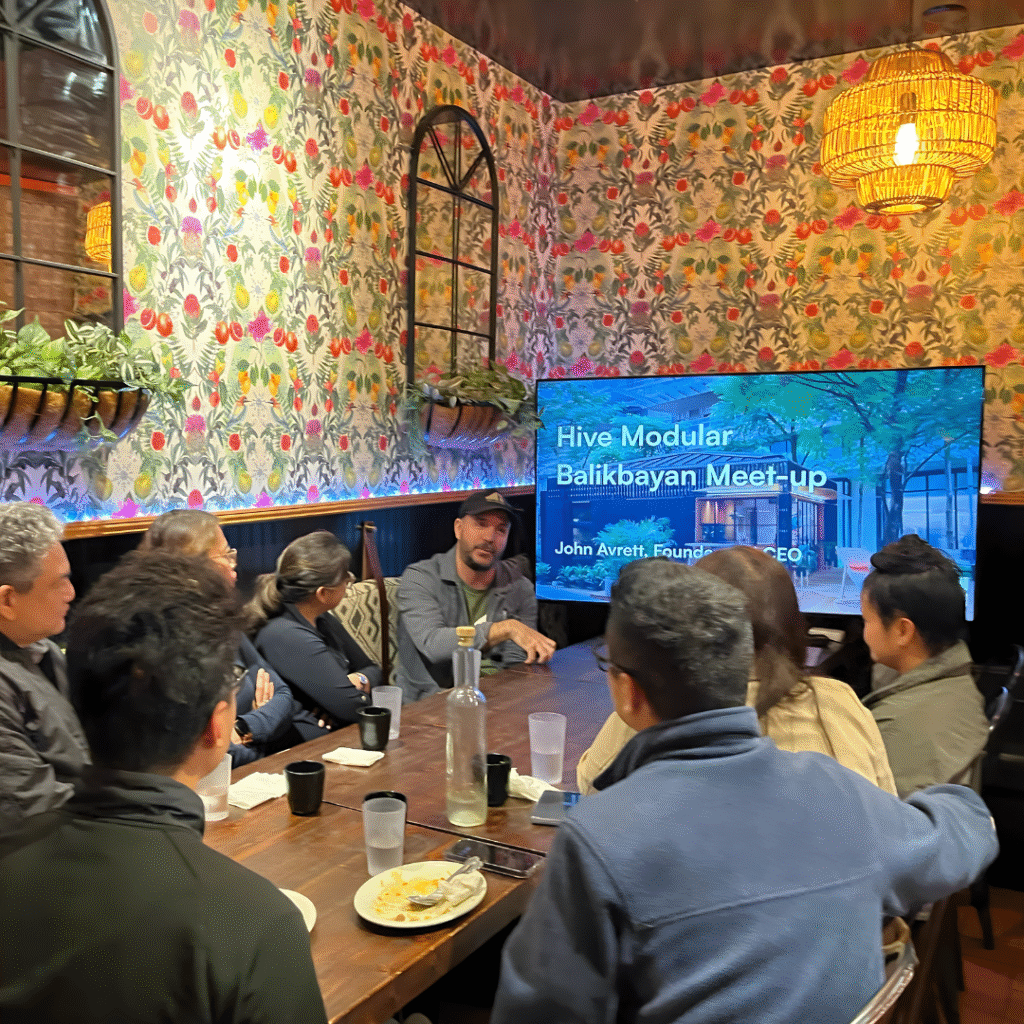

The company was founded in 2023 by John Avrett, whose background in aerospace engineering and international trade shaped his perspective on quality, precision, and efficiency. Rather than viewing construction as a one-off project, he sees it as a process that benefits from repeatability and consistency—an idea that has long been at the heart of modular housing. By fabricating structural components in a controlled environment and transporting them to the jobsite for installation, Hive is applying a familiar strategy to a market that is only beginning to understand its value.

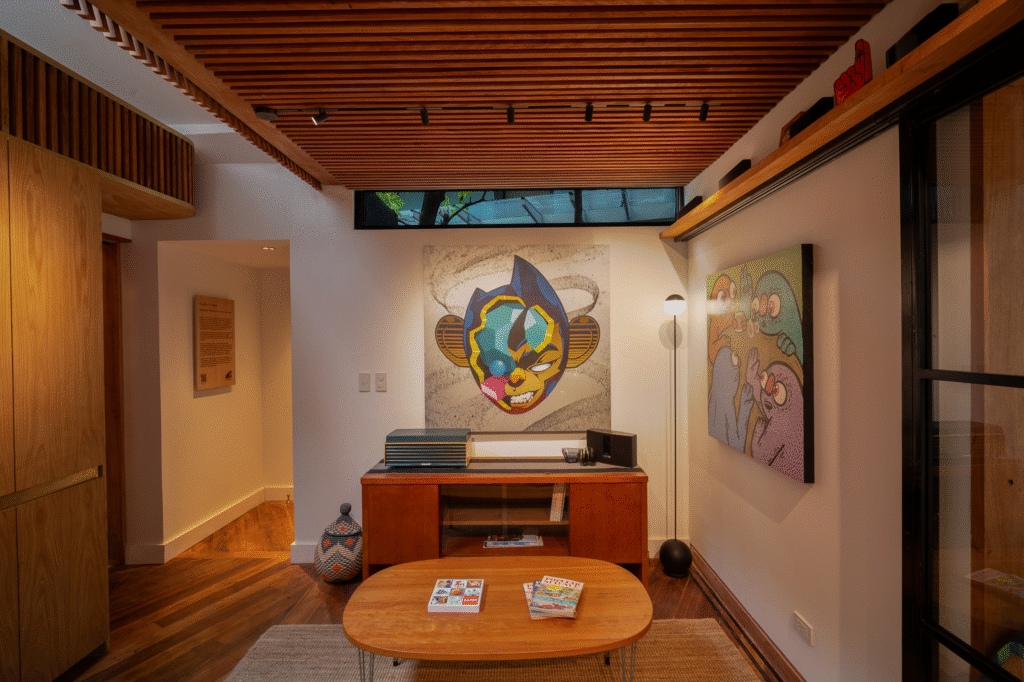

Where Hive truly differentiates itself is in design. Its flagship Casita series emphasizes compact, efficient layouts that prioritize both indoor and outdoor living. The floorplans are intended to feel open and flexible, with seamless transitions between interior and exterior spaces. In many parts of the Philippines, lifestyle is closely tied to outdoor activity, social gatherings, and climate-conscious design. Hive’s layouts reflect that reality rather than simply importing a Western-style modular home and hoping it fits.

This focus on floorplan and livability may seem like a small detail, but it is often where modular builders succeed or fail. Around the world, the companies that gain traction are the ones that adapt their product to local culture, climate, and expectations. Standardization improves efficiency, but thoughtful design builds acceptance. Hive’s approach demonstrates that the future of offsite housing isn’t about copying models from other countries—it’s about translating proven methods into forms that resonate locally.

The company’s product range reflects this balance. The Casita X offers a compact, move-in-ready home with integrated outdoor space, while the more affordable Casita M targets scalability and wider accessibility. Both models arrive largely complete, reducing onsite disruption and shortening the overall construction timeline. For buyers who have endured months or even years of traditional building, that level of predictability can be compelling.

Hive also emphasizes local manufacturing and supply chains. By producing homes domestically, the company aims to support skilled labor and engineering talent while reducing reliance on imported materials. This aligns with a broader global trend: countries are beginning to see offsite construction not just as a housing solution but as an industrial strategy that strengthens local economies.

Sustainability plays a role as well, though in a practical sense. Material optimization, efficient construction, and responsible sourcing are part of the company’s process. These are not radical innovations but rather sensible steps that reflect the growing expectation that housing must address environmental concerns alongside affordability and speed.

One of the biggest hurdles for modular builders everywhere—financing—remains a challenge in the Philippines as well. Traditional lending structures are designed for conventional construction schedules, not factory-built timelines. Hive is working to develop partnerships that better align financing with prefabricated delivery, an effort that could help accelerate broader adoption.

What Hive Modular represents is not a revolution in offsite construction. The industry has already developed the tools, methods, and technologies needed to deliver housing efficiently. Instead, the company is a reminder that success often depends less on invention and more on application. Bringing proven approaches to new markets, while adapting design to local lifestyles, is where real progress happens.

For those of us who have spent decades watching modular and offsite construction evolve, this story feels both familiar and encouraging. The global industry doesn’t need more buzzwords or reinvention. It needs thoughtful execution, local relevance, and products that people genuinely want to live in. Hive Modular may be young, but by focusing on design and cultural fit, it is demonstrating that the next phase of offsite growth will come from companies that understand not just how to build—but where and for whom they are building.

.

With more than 10,000 published articles on modular and offsite construction, Gary Fleisher remains one of the most trusted voices in the industry.

.

CLICK HERE to read the latest edition

Contact Gary Fleisher